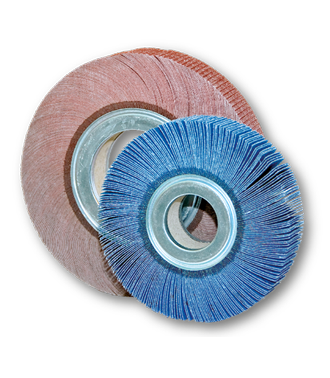

The flap wheels in abrasive cloth cab be suitable such as:

The flap wheels in abrasive cloth cab be suitable such as:

Rough-hewing and finishing of large flat, concave or convex surfaces;

Inner and outer sanding of tanks, containers and pipes;

Finishing of irregular profiles such as handles, taps and molded parts;

Removal and cleaning of welding beads;

Preparation of surfaces for pre-varnishing, pre-teflon, pre-coating with anti-corrosion protection and pre-polishing up to very fine grain to facilitate mirror polishing etc.

All our products comply with a guaranteed product cycle, from the purchase of raw materials to construction and distribution of flexible tool. TOOLFLEX can control the quality of its entire production cycle.

Advantages

- Abrasive cloth blades (support x-flex) made of aluminum oxide (AO) are anchored and blocked in a high thermos – mechanical resistance homogeneous resin core guaranteeing secure abrasive cloth hold.

- The two head flanges are made of galvanized steel and are flat for counter flange coupling of machine or manual tools. All wheels are calibrated and balanced for perfect operations.

- The flap wheels are singularly balanced one at a time to guarantee stability when used on automatic and semi-automatic machines, manual column machines, centerless, flat satin machines, balanced satin machines, untwisters, planetary, rotating tables, transfer or lines with robots, coils (with special Toolflex skeletonized wheels from 200 mm to 2000 mm long, diameter 350-400-450 mm) and more.

- The cloth used guarantees an excellent balance between flexibility and resistance.

High availability of diameters and heights, for the right combination of manageability and duration.