TOOLFLEX experience, always dedicated to users’ needs, created a new tool: the “Conical Flexible Wheel”.

TOOLFLEX experience, always dedicated to users’ needs, created a new tool: the “Conical Flexible Wheel”.

It is an innovative, reliable and versatile tool, unique on the market, capable of changing the working method for roughing-out and finishing of surfaces. These processing techniques have the function to optimize the roughness of various products, eliminating irregularities and defects, and also increasing both performances and duration of the material itself; appearance and quality benefit from this new method too.

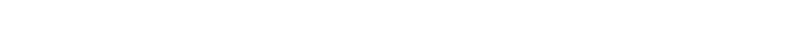

The new tool is available in three format: Ø 230mm, Ø 170mm, and Ø 110mm.

The TOOLFLEX conical flexible wheel is able to overcome the inconveniences generating from the tools now available on the market, such as:

The new tool’s flexible structure resolves the problem connected to the creation of marks or scratches on the worked surface, defects coming from the rigidity of the tool adopted in the working process.

The conical wheel’s particular geometrical characteristics have been designed with the aim to guarantee a top quality finishing of products with an irregular and rounded surface.

Indeed, thanks to the particular functional shape and to the flexibility of the abrasive flaps, the new TOOLFLEX “conical flexible wheel” is placed in the middle between traditional flap wheels and flap discs, with the possibility to obtain excellent results in terms of lifetime, reliability, quality and consistency of the performances.

Fields of application

The new tool can be implemented in different sectors: iron and steel, timber, plastic, glass, marble, bodywork etc.

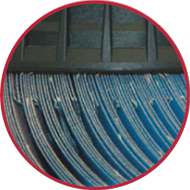

CONICAL FLEXIBLE WHEEL

CONICAL FLEXIBLE WHEEL

It consists of abrasive flaps, firmly fixed to the upper part of the support and positioned next to each other; it can be made of different materials and different grits.

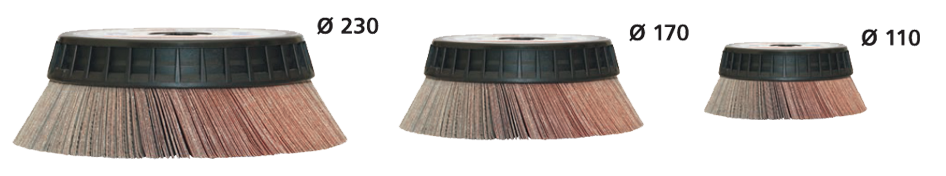

CONICAL FLEXIBLE WHEEL WITH SPACED SHAPED

CONICAL FLEXIBLE WHEEL WITH SPACED SHAPED

In this model the abrasive flaps are positioned slightly spaced from each other; the result is a much greater flexibility of the flaps themselves.

This tool is particularly suitable for all the work where the production have round and irregular surfaces and, due to a better cooling of the blades, in conditions of extreme heat. The flaps can be made with different materials and different grits.

MIXED CONICAL FLEXIBLE WHEEL

MIXED CONICAL FLEXIBLE WHEEL

It is produced by alternating abrasive flaps and Scotch Brite® flaps.

This tool is ideal to obtain a targeted result of surface finishing, alternating Scotch Brite® flaps and different abrasive materials and different grits.

COTTON CONICAL FLEXIBLE WHEEL

COTTON CONICAL FLEXIBLE WHEEL

This tool is made of cotton flaps positioned next to each other; different colors mean different hardness of the cotton. Suitable for polishing and removing small defect left from the abrasive.